Introduction

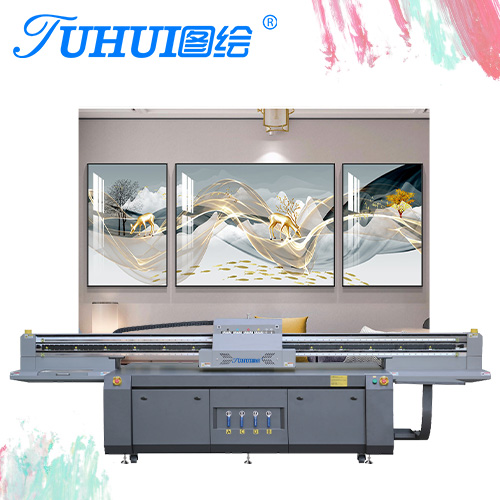

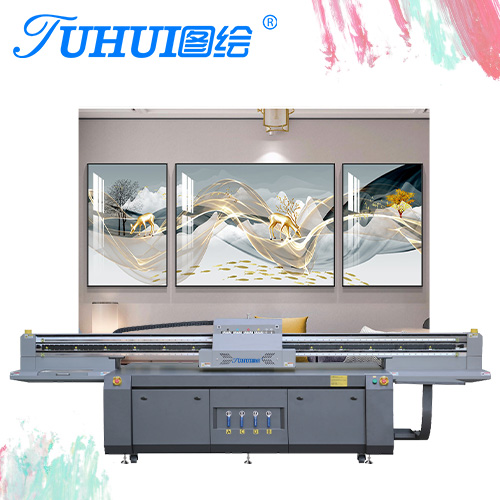

I want to read this article, you already know something about uv flatbed printers. You also want to know the principle of uv flatbed printer, right?

Details

The principle of uv flatbed printer mainly includes three principles, namely printing principle, color principle and imaging principle. Among them, the printing principle affects its printing range, the color principle affects the printing effect, and the imaging principle affects the printing efficiency.

Printing principle:

The uv flatbed printer uses the piezoelectric inkjet printing principle, which is different from the thermal foaming type, and also different from the principle of screen printing, thermal transfer, pad printing, etc. It controls the ink through the internal voltage of the nozzle, and ejects it on the desired printing. The surface of the material. Therefore, it is not necessary to make a plate, film, color register and other processes before printing.

Since there is no direct contact with the material, the air-jet ink prints the ink on the surface of the material, which broadens the printing range of the material and is no longer limited to one material, such as glass, ceramic tiles, acrylic, metal, leather, etc. in daily life. All materials can be printed by one machine.

Color principle:

The basic colors are C (cyan), M (product), Y (yellow), K (black), plus W (white), in addition to LC light cyan, LK light black, LLK light black and Spot colors are green, silver and other colors, according to the actual material printing pattern needs to match the appropriate color.

The color software used includes photoprint, Montai, RIP, etc. These three softwares are similar in function, and they are all edited before the pattern is printed.

Because of the white function, two functions are realized. One is the relief effect, which uses white ink to form uneven heights on the surface of the material, and then prints colors on the surface. The other is a color case printed on a dark material with white ink on the bottom.

Imaging principle:

Imaging is achieved by the chemical reaction between the photosensitive curing agent in the uv ink and the ultraviolet light waves irradiated by the LED lamp, and it is not traditional thermal baking or natural drying. Due to the short reaction time, the pattern can be cured within 3 seconds, which shortens the production time of the finished product.

However, due to the matte nature of uv ink, the imaged pattern is dark and not bright enough. In response to this situation, a layer of transparent liquid can be sprayed on the surface of the pattern in the form of uv varnish (varnish) to achieve a brightening effect.

In the actual printing process of the uv flatbed printer, the printing quality of the material is achieved by a combination of various factors such as the printing environment, printing speed, feathering, image processing system and nozzle movement system. This depends on the manufacturer’s training on the one hand. On the other hand, it comes from the continuous accumulation of experience. The uv flatbed printer can print directly on the glass. Such as the common plane effect, hollow effect, relief effect.

After reading this article, I think you have been deeply impressed by the principle of uv inkjet printers, plus your knowledge of flatbed printers, I think now you will know what type of printer and what configuration of uv printer is right Your business has helped. Also know how to choose the right products.